Aspherical components in optical systems can increase the free design variables without introducing new aberrations. That brings improved imaging quality and reduced size and weight. Aspheric components are widely used in high-end optoelectronic instruments, such as space and ground-based astronomical telescopes, deep space exploration platforms and earth observation optics.

The two critical specifications of a telescope system are the angular resolution (AR) and light collecting capacity (LCC). These specifications are closely related to the aperture of the system. AR is inversely proportional to the telescope’s diameter, while LCC is proportional to its squared value. The larger the aperture, the higher and stronger the AR and LCC. Consequently, increasing the aperture becomes essential to improving the telescope’s performance. That is why both astronomy and earth observing communities need large telescopes.

The larger size of the primary mirror in modern ground-based telescopes and space cameras imposes demanding and stringent requirements on mirror materials and full-spatial frequency (FSF) shape error control. Breakthroughs in mirror materials that support accurate and efficient manufacturing of large aspherical mirrors are urgently expected.

In a new paper published in Light: Science & Applications, a team of scientists led by Professor Xuejun Zhang from the Changchun Institute of Optics, Fine Mechanics and Physics have developed some new techniques for manufacturing large mirrors. Their paper, titled “Challenges and strategies in high-accuracy manufacturing of the world’s largest SiC aspheric mirror,” saw the team build its largest aspheric mirror.

SiC has higher specific stiffness (SS) and dimensional stability (DS). It is well suited for harsh environment applications. The reaction-bonded silicon carbide (RB-SiC) process can produce a semi-closed back structure, further increasing its SS and DS. Large aperture SiC mirrors are becoming a new favorite in the telescope community worldwide. Manufacturing large SiC mirrors with a diameter of more than 2 m is extremely challenging. There are also complex physical phase changes and chemical reactions.

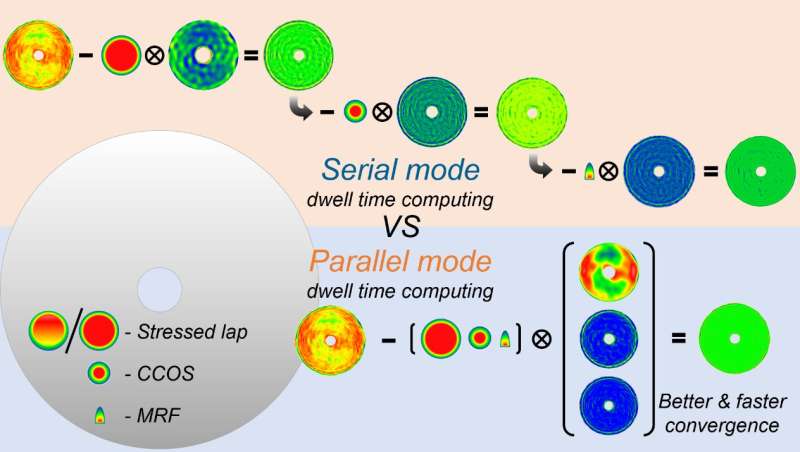

Existing technology is not adaptable to mirrors over 1.5 m in diameter. The difficulty of manufacturing aspheric mirrors is proportional to the third power of the aperture. The largest magnetorheological finishing (MRF) polishing equipment has a maximum processing size of 2.5 m.

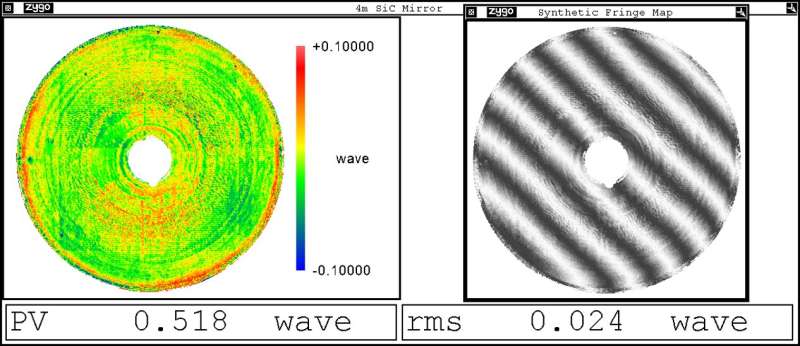

The researchers have manufactured a 3 m diameter monolithic SiC mirror blank. They also made a 4.03 m diameter SiC mirror blank by reaction-formed joint technology. Using a home-built MRF24 polishing machine with a maximum processing range of 4.5 m diameter, a 4.03 m SiC aspheric mirror was polished to high accuracy.

The researchers also proposed a PVD cladding process to improve the substrate surface quality. A thin cladding layer of Si was deposited on the substrate surface, with its defects covered with silicon material. The low processing temperature saw a very low deformation rate.

Provided by

Chinese Academy of Sciences